Garage Updates

It might be a bank holiday, but we’re still hard at work…

With the unsprung mass and suspension finished we’ve been able to put the car on the ground, so we now have a rolling chassis!

This is allowing us to finalise our drivetrain by putting our driveshafts in, which will be done over the next couple of days. We are initially using plastic mock-up driveshafts to make sure we have the correct length before cutting the real drive shafts. Measure twice cut once and all that!

The finalised unsprung mass has also allowed us to begin assembling the braking system. The first thing we did was mount the pedal box in the car, and then mount the brake calipers to our new uprights. From here, we’ve begun cutting the brake lines to length, and routing them through the chassis.

In our composites area, we’ve been preparing the nosecone, engine shroud and side panels for painting. This involves repairing any imperfections from the layup, preparing the surface for paint, and mounting the quick release fasteners for the chassis. Tomorrow the painting begins!

Check out a vlog of the day at https://youtu.be/Ulg4KxMQGMw

Also, remember there is still time to come to our car launch on May 31st! Get your free tickets HERE. Beer is on the house…

Garage Updates

Today the unsprung mass and suspension underwent a lot to prepare it for lowering the car. We’ve also focussed on powertrain assembly, the fuel tank catch cans and swirl pots were finalised and mounted in the car, and all the lines and fittings assembled. The silencer fabrication was finalised, which allowed us to assemble it to the exhaust and chassis, which therefore allowed us to finish the exhaust shroud bodywork.

Over in electronics, the 4th and final modular section of the wiring loom is nearing completion, and The ECU and power board are now connected to the rest of the loom!

Garage Updates

busy day in the garage! Our Head of Powetrain, Peter, has written today’s update:

The radiator has been refurbished and the swirl pot was manufactured, thanks to G&M for both of those things. This has allowed us to assemble all the features of the cooling system and install the coolant plumbing, composed of aluminium tubing and rubber hosing, (what I was doing today). This means we can next assemble the sidepod which will both optimise airflow through the radiator and protect it from damage.

The fuel tank has now been fully welded and has been installed into the chassis, thank you to G&M for manufacturing that. The fuel injector housings have also been attached to the engine head. This has allowed us to assemble all of the fuel lines connecting the tank to the fuel injectors, meaning our fuel system is very near to completion.

Check out today’s vlog: https://youtu.be/A6Y21l51a_g

Garage Updates

Exam season is over, so we’ve raced back to the garage to continue preparing UGR-19 for comp (less than 8 weeks to go…).

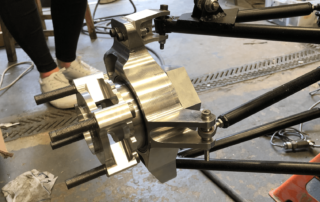

Work has begun assembling our new unsprung mass to fit within the the new 10″ wheels. This will be the biggest weight saving on the car at over 14kg!

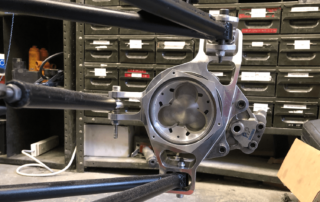

Uprights Delivery

Our teeny tiny super shiny UGR-19 Uprights have arrived!

🗣 “We would like to say a huge thank you to Tannlin for manufacturing them for us. This new design has a 42% mass reduction when compared to last year. Packaging an upright within the 10” wheels was certainly a challenge but it was a honour to work on them as my Final Year Project” – Cara MacKay, Head of Unsprung Mass

Special Visitors

Today we welcomed some local high school students to our UGR garage! UGR’s Head of Unsprung Mass, Cara, spoke to the students about Formula Student, our cars and studying engineering at UofG. The visit was part of our Outreach program which aims to encourage local students to consider studying engineering – hopefully we’ll see them on the UGR team in a few years!

Hubs

Our new hubs have arrived! “The hubs for UGR-19’s unsprung assembly have reduced the overall weight of the hub assembly by 30% as well as reducing the number of assembly features, and all within the smaller space of our new 10″ wheels. The photos speak for themselves!” – Finlay McNeil, Hubs Designer

Chassis Update

Our chassis is back from G&M after sandblasting and a fresh coat of paint. Time for final assesmbly!

An Exciting New Update…

To welcome in April we thought we’d share our biggest and most ambitious design improvement in UGR’s history. After months of material research, hours of structural simulations and many team branding meetings – here it is. Enjoy!

Wheel Delivery

Our new 10″ wheels from Braid have arrived! UGR-19’s most notable change is the reduction from 13” wheels to 10” wheels, accompanied by smaller hubs, uprights and brake disks, consequently resulting in a reduced vehicle mass.

Social